California Management Review

California Management Review is a premier professional management journal for practitioners published at UC Berkeley Haas School of Business.

by Patricia Carolina Garcia Martin, Debadrita Panda, and Vinit Parida

Image Credit | eruppee

Achieving a sustainable development is paramount to secure global growth without compromising future needs. While this goal is a must on everyone’s agenda, resource-intensive industries such as manufacturing and processing face a greater scrutiny of their operations1. While the wide variety of activities developed by industrial firms negatively impact sustainability pillars, room for improvement translates into opportunities for innovation2. The flat glass ecosystem – comprising the design, production, installation, and demolition of windows for building constructions – is an example of how to approach the sustainable transition with eager eyes. Indeed, actors along the value chain are aligning their efforts towards a circular driven transformation. Following circularity principles, the common goal is to close the material loop extending the life cycle of windows while intensifying the circulation of culets through end-of-life recycling. However, transforming linear practices is not an easy task and competing priorities create a burden to stay in the loop and achieve the desired circular outcomes3.

Hopkinson, P., Zils, M., Hawkins, P., & Roper, S. (2018). “Managing a Complex Global Circular Economy Business Model: Opportunities and Challenges.” California Management Review, 60(3), 71-94.

Frishammar, J., & Parida, V. (2019). “Circular Business Model Transformation: A Roadmap for Incumbent Firms.” California Management Review, 61(2), 5-29.

The authors of this article have worked in collaboration with key stakeholders from the flat glass ecosystem closing the window loop, from design and manufacturing to demolition, crushing, and disposal. Through circularity driven workshops and discussions, we have learnt about the efforts and initiatives deployed to transition into a circular industrial ecosystem. Nonetheless the common goal of the involved parties, the particularities of the product and the rigidity of established processes represent a complex combination stagnating the sustainable transformation. It became evident that for change to happen, new ecosystem wide practices had to be established. We want to provide an open window to the insights gained from this collaborative project and inspire other industrial ecosystems to follow suit in advancing the pace to circularity. The remainder of this article is structured in three main parts. First, we present the flat glass ecosystem and provide an overview of their circularity goals. Second, we identify and explain the barriers gatekeeping the progression of sustainable development. Lastly, we highlight three main practices being deployed to advance circularity. In doing so, we shed light into the complexity of industrial sustainable development and provide guidance to approach the circular transition at ecosystem level.

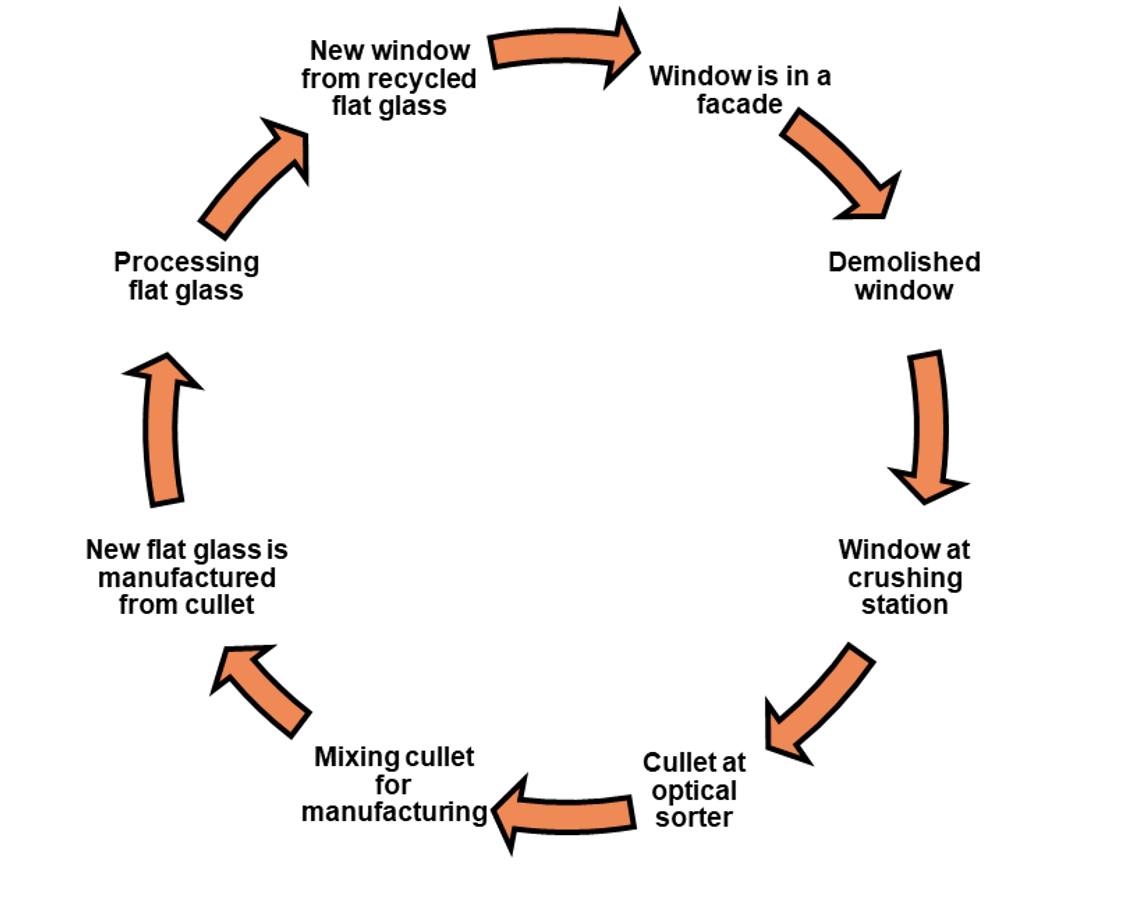

Flat glass is one of the main components used in the construction and renovation of windows in building constructions. Buildings have a key role to play in the transition to a circular economy, and window flows are becoming a pillar of the sustainable construction agenda. The goal is dual, to design less resource intensive buildings and to reduce building waste going landfill to zero. The flat glass ecosystem is paving the way towards closing the loop in the design, production, handling, and disposal of windows for building construction and renovation (Figure 1).

Figure 1. Flat Glass Ecosystem:

Closed-loop Flow

Primarily made of sand, flat glass window production is dependent on a finite raw material constraining the future resilience of the ecosystem. In addition, the extraction, lamination, and processing of flat glass constitute energy intensive processes, releasing high amounts of CO2 to the environment. The good news is that flat glass can be recycled unlimited times which enables to repurpose and re-use the same materials in multitude cycles. For instance, substituting sand for recycled flat glass in new windows can lead to the reduction of CO2 footprint by 54% maintaining the same level of output.

The flat glass ecosystem aims to transition from linear disposal of windows and its associated raw materials to a preventative approach. The goal is to reduce material consumption and substitute current linear processes for longer cycles, where circular flows of flat glass lie at the heart of the ecosystem. Stringent diagnosis, removal, dismantling, and sorting processes need to be deployed, requiring the efforts and alignment of multiple ecosystem stakeholders. Introducing processes also imply new ways of working which tend to clash with established habits and procedures. Beyond alignment and culture, costs and infrastructure deficiencies also place a toll in the circular agenda. These and other barriers are discussed in the following section, enlightening industry and policymakers about the constrains of the flat glass ecosystem to stay in the loop.

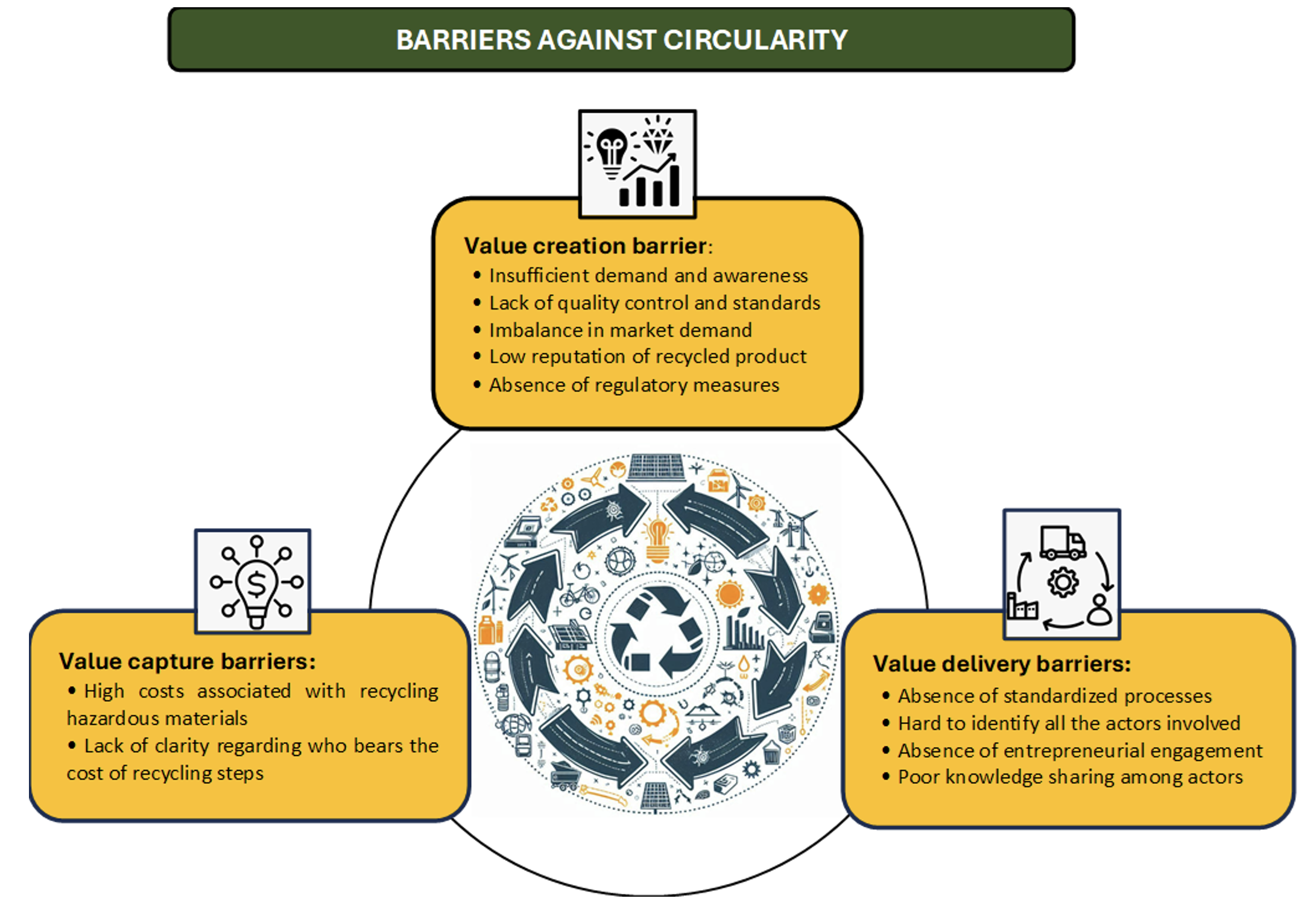

Traditional heavy industries like flat glass manufacturing face complex challenges in transitioning to sustainable practices, especially in a circular economy. We have identified and structured the main barriers into value creation, delivery, and capture categories (Figure 2). This segmentation not only clarifies how each barrier affects different business model functions but also enables firms to develop more targeted strategies to overcome them3. By understanding where obstacles impact the production, distribution, and monetization of sustainable products, firms can align their efforts more effectively, driving innovation and achieving long-term sustainability goals4.

Figure 2: Barriers to the circular transition in the flat glass ecosystem

Value creation: The primary value creation barrier refers to insufficient end-user demand and awareness. Many consumers and businesses are unaware of the environmental benefits of recycled flat glass, leading to low market interest. For instance, builders may continue to use virgin glass for new construction projects simply because they are not informed about the advantages and availability of circular options. Lack of quality control and cleanliness standards in recycled glass production results in inconsistencies, which undermine market confidence. This barrier prevents to meet the performance standards required for high-profile architectural projects. Scaling efforts are impacted by an imbalance in market demand between glass types, with container glass being more used due to its extensive applications in packaging. This disparity makes it harder to justify the investment in large-scale flat glass recycling infrastructure. Low reputation of recycled flat glass products deters adoption, being perceived as inferior in durability and aesthetics. The value of new flat glass products is more desirable in the high-end construction market. The absence of regulatory measures or guidelines to certify the quality of recycled flat glass also contributes to uncertainty regarding performance and reliability.

Value delivery: Value delivery in the flat glass industry is hampered by logistical barriers. First, the absence of standardized processes for segregating glass at the end of their life cycle adds complexity to the circular transition, as various glass types—laminated, coated, or tempered—require different treatments. Moreover, the flat glass recycling ecosystem lacks visibility, making it difficult to identify all the actors involved, from demolition companies to recyclers. The absence of entrepreneurial engagement further stifles the transition, leaving a gap in innovative solutions that could address the industry’s complex circularity needs. For example, the flat glass sector lacking fresh ideas for processing end-of-life products efficiently. Poor knowledge sharing among industry stakeholders is another barrier to effective value delivery. Without robust communication channels, actors along the supply chain—from demolition contractors to recycling firms—often operate in isolation, unaware of more efficient ways to handle or repurpose waste. For instance, a demolition company may be unaware of a nearby recycler capable of processing certain types of glass, leading to missed opportunities for collaboration.

Value capture: Capturing value from circular processes in the flat glass industry is challenging due to the high costs associated with recycling hazardous materials. Recycled flat glass, unlike other types of glass, incurs additional processing costs because it is often classified as hazardous waste. This makes the recycling process more expensive, as specialized handling and cleaning are required. Furthermore, there is a lack of clarity regarding who bears the cost of recycling steps, such as transportation to recycling centers. For example, while manufacturers might be responsible for recycling, it remains unclear who should cover the transportation costs. This uncertainty around cost allocation discourages companies from engaging in circular practices, as the financial risks are not clearly defined.

The identified barriers show how transitioning towards a circular economy is not straightforward but rather a complex and uncertain journey. Our findings from the flat glass ecosystem show the relevance of shared circular foundations that strengthen the commitment and enhances a common vision among the parties5. We identified three best practices leading the way forward to the sustainable development of building construction windows: conscious education, design for circularity, and decentralisation of loops (Figure 3). An important aspect to highlight is the multidisciplinary character of the practices, requiring the involvement and joint participation of a wide variety of actors.

Conscious Education: out with the old, in with the new. An effective change requires strong building blocks that break out with old habits and bring in a new mindset. Teaching, promoting, and creating awareness of circular economy in the ecosystem is crucial to achieve the desired sustainable development. Conscious education involves the design and delivery of training programs tailored to specific stakeholders highlighting the DO’s and DON’Ts of their contribution to the circular transformation. For instance, understanding the implications of user behaviour can help increase the commitment of end users to safeguard the end-of-life value of products for circularity. Society, including citizens and entities (i.e., educators, city halls, funding agents), should be involved in this practice to legitimate conscious programs and bring attention to circular behaviour.

Design for Circularity: do not start the house by the roof. Transitioning towards a circular economy is a holistic journey where outputs are as relevant as inputs. Ensuring the application of circular principles from the initial steps of the supply chain is imperative for the achievement of a well cemented sustainable development in the ecosystem. Design for circularity involves the establishment of guidelines for the design processes with circular goals in mind. For instance, architects can influence changes in design by asking to use recycled raw materials, increasing the demand for circularity in the industry. Policy makers should be involved in this practice to define the value of recycled inputs and contribute to a standardised design for circularity benchmark. Demand and regulatory changes will enable and encourage producers and OEMs to make conscious choices in the design and manufacturing of flat glass.

Decentralisation of Loops: join forces to cover all angles. Circularity implies an integrative approach covering all aspects of the product life cycle. Activity distribution in the ecosystem is essential to leverage synergies and to identify new partnerships for sustainable development. Decentralisation of loops involves moving circular activities closer to the origin or delegating them to expert third parties. For instance, crushing firms can demand to develop their activity at demolition sites for reduced costs, increasing the efficiency and effectiveness of the transition. Experienced circular brokers (i.e., cross-industry intermediaries) should be involved in this practice to carefully assess and take over activities where the ecosystem is unable to outperform. Bridging gaps in the ecosystem will enable and encourage recycling actors to engage in profitable circular processes through efficient role and responsibility distribution.

Figure 3: Practices advancing circularity in the flat glass ecosystem

Policymakers and managers responsible for circularity decisions can benefit greatly from this article. For policymakers, understanding the barriers to value creation, delivery, and capture in the flat glass industry provides a clear roadmap for developing supportive regulations. For instance, introducing quality standards for recycled flat glass would boost market confidence, while subsidizing transportation costs for recycling centers could resolve cost allocation issues and encourage more firms to participate in circular practices. For managers responsible for making decisions related to circularity, this article highlights actionable strategies such as investing in conscious education programs to shift mindsets and enhance internal capabilities for recycling. Additionally, managers can leverage the idea of decentralizing recycling activities, partnering with expert third parties like circular brokers to handle processes that may be outside their expertise, reducing costs and improving efficiency. By following these recommendations, both policymakers and managers can help advance the industry’s shift toward a more sustainable and circular future.