California Management Review

California Management Review is a premier academic management journal published at UC Berkeley

by T S Krishnan and Archisman Majumdar

“Supply Chain Risk Management is an issue that many companies face, and yet few companies know how to deal with it in a systematic and pragmatic manner.”

-Thomas A. Debrowski, Executive Vice President, Worldwide Operations, Mattel, Inc.

The ability to proactively identify and resolve supply risks is an important driver of competitive advantage for manufacturers. Supply disruptions due to COVID-19 have cemented the importance of this activity in manufacturing firms. Though supply chain planners have been capturing the risk-related information in textual form in enterprise systems, they are seldom used proactively. Manually analyzing hundreds of such textual bits for a thousand parts/components is difficult, time consuming, and error prone. For example, a single product could accumulate 400,000 comments over the course of a year! Emerging technologies like AI can be harnessed to automate such analysis and provide predictive insights. In this article, we propose a DMAIC-based framework 1 that can be readily applied by managers and supply chain leaders to automate processes and distill insights to proactively identify and resolve supply risks.

More than 80% of organizations’ business processes resides in unstructured (text) form – like internal documents, e-mails, reports, invoices, customer chats, etc. 2 Advancement of computing power and Artificial Intelligence (AI) technologies has enabled organizations to analyze this unstructured data using Natural Language Processing (NLP). NLP is an interdisciplinary field that integrates computer science, linguistics, and AI to process, understand, and analyze textual data. NLP helps to understand meaning from textual data. For example, given a chunk of text, NLP can help identify the sentiment, topics discussed, personally identifiable information, meaning / intent, and so on.

Over the years, supply chain executives have been involved in setting up robust digital processes to identify, assess, and mitigate risks across their organizations’ supply chains. Recently, scholars and practitioners have begun to experiment with AI-based techniques to manage supply chain risk. 3 A 2018 article in the Harvard Business Review, titled “The Death of Supply Chain Management” 4 noted the following: “With a digital foundation in place, companies can capture, analyze, integrate, easily access and interpret high quality, real-time data – data that fuels process automation, predictive analytics, artificial intelligence and robotics, the technologies that will soon take over supply chain management.” The article described a future virtual center, filled with specialized analysts with expertise in operations/supply chain and technology, which provide end-to-end transparency of supply chains. We extend this article further by illustrating the use of bottom-up grounded approach to manage supply chain risk using digital technology. We take an actual job function in an organization’s supply chain and break it down into tasks. We select one task and structure the problem making it amenable to apply NLP.

Supply and demand planners perform a critical job/function in a firm’s supply chain management. The key tasks of this job include the following:

We focus on making one task easier using AI. The task we chose is to proactively identify and resolve supply risks. In this article, we develop a practical approach that can help identify reasons for supply chain interruptions. This framework is based on NLP done on historical textual data. The framework can be adopted by the planning function of a supply chain in any firm.

Supply and demand planners enter or update comments in their respective enterprise systems whenever they face interruptions in the supply chain. Interruptions can be considered an early indicator of potential risks. An example of a typical comment is as follows: “Shipment is postponed due to supply alert on data integrity.” In this sentence, the cause of shipment interruption is due to an issue with the supplier’s data integrity. Such an interruption could lead to supply risks. Another example of a comment is as follows: “Units in Bangalore awaiting local release. Local release delay due to artwork issue.” This comment means that products in Bangalore warehouse are awaiting release into the market due to a packaging artwork issue. In this sentence, the cause of interruption is an artwork issue.

DMAIC is a process improvement framework. Historically, this has been used extensively to drive Six Sigma projects. We leverage this framework to drive the process to create actionable insights to proactively identify and resolve supply risks.

a. Define

This step includes clearly articulating the business problem, project scope, project timelines, and how a sucessful solution would look like.

b. Measure

This step focuses on measuring the existing process; i.e. how the process is currently being done, how much time does it take to manually execute the process, and so on. This helps develop baseline measurements and will be helpful to quantify results of an improved process.

c. Analyze

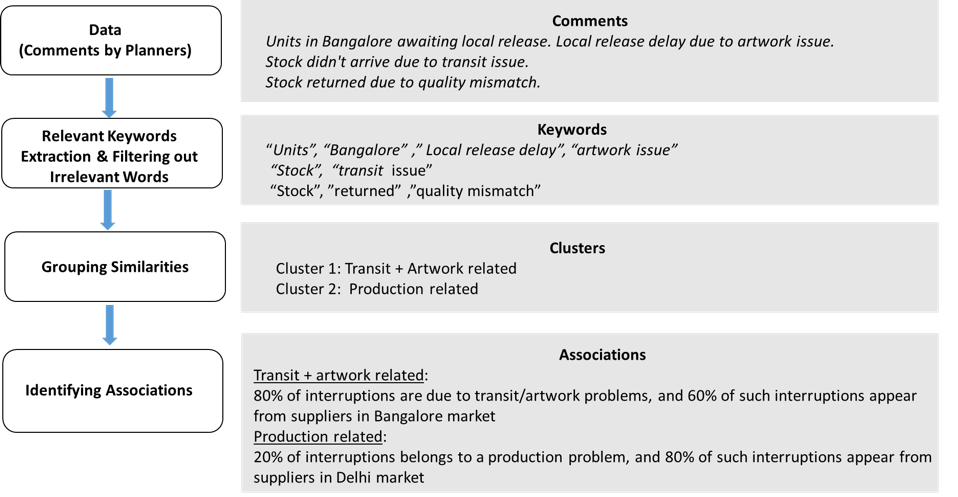

This is the data analysis step. This step details how to analyze the data stored in enterprise systems. A lexicon of words relevant to supply chain interruptions is prepared based on domain knowledge. After filtering for relevant terms (chunks of sentences representing the reasons for interruption), Topic Modelling 5 can be done to make clusters of similar reasons. This can help identify the reasons of supply chain interruptions with high granularity.

The NLP model consists of executing a 4-step process depicted in the figure below.

d. Improve

In this step, the actual process improvement (based on the analysis) is done. For example, an improved process would include vendor prioritization after knowing pros and cons of all vendors. Suppose, after analysis we know about in-transit/quality issues from a vendor based in Bangalore. This insight is incorporated while planning vendors in the supplier selection process. This could lead to including vendors from Delhi or other locations to mitigate the risk. In essence, the manufacturer is able to prioritize vendors based on quality, lead time requirements and so on.

e. Control

The improved process should not degrade over time – it must be controlled so that the improved process works well every time. This step involves exploring the following questions: Have the improvement met the objective outlined in the Define step? How much better (in terms of time savings, ROI) is the new process when compared to the old process?

Acknowledgement: We thank Dr. Jai Ganesh and Ashish Bharti for providing insightful suggestions.

Define, Measure, Analyze, Improve, and Control. ↩

https://www.forbes.com/sites/forbestechcouncil/2017/06/05/the-big-unstructured-data-problem/ ↩

Baryannis, G., Validi, S., Dani, S., & Antoniou, G. (2019). Supply chain risk management and artificial intelligence: state of the art and future research directions. International Journal of Production Research, 57(7), 2179-2202. ↩

https://hbr.org/2018/06/the-death-of-supply-chain-management ↩

Topic Modeling is an unsupervised method that organizes/groups a collection of text into categories. ↩